Penetration Grade of Bitumen

Grades of Bitumen

Bitumen is usually characterized in the following three types of grades:

- Viscosity grades

- Penetration grades

- Density grades

Definition of penetration Grade

The penetration grades bitumen is refinery bitumen which is produced by different viscosity. In fact, Penetration bitumen is semi hard black material known as petroleum grade bitumen. The penetration test is carried out to characterize the bitumen, based on the hardness. Therefore, it has the name penetration bitumen.Penetration Grade Bitumen is a standard bitumen usually used as a Paving Grade Bitumen essential for road construction and for the production of asphalt pavements with superior properties, and it’s very important once it bounds the aggregates and creates a unique cohesion and stability to the bituminous mix.

Actually it is Bitumen classified using the penetration property. Penetration grading’s basic assumption is that the less viscous the asphalt, the deeper the needle will penetrate. Bitumen which is produced during the process of oxidation of vacuum bottom (the Bitumen production feedstock that derives from distillation tower residue in vacuum oil refineries) at bitumen production unit in a manner that its penetration point (kind of test to indicate the hardness of bitumen) in specified group is classified in different grade of it.

This grade of Bitumen is mainly used in the manufacture of hot mix asphalt for bases and wearing courses.

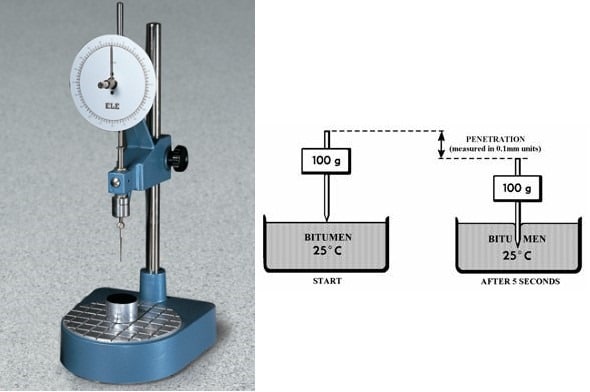

The penetration of bituminous material is its consistency expressed as

the distance in tenths of a millimeter that a standard needle penetrates vertically into a specimen of the material under specified conditions of temperature, load and duration of loading.

Grades of straight-run bitumen are designated by two penetration values, for example, 40/50, 60/80, 80/100 etc.; the Penetration of an actual sample of the bitumen in any grade should fall between the lower and upper value given.

Penetration Grade bitumens are specified by the penetration and softening point test. Designation is by penetration range only. The penetration grade bitumens have a thermoplastic property which causes the material to soften at high temperatures and to harden at lower temperatures. This unique temperature/viscosity relationship is important when determining the performance parameters such as the adhesion, rheology, durability and application temperatures of bitumen.

Sources of Bitumen

Bitumen is generally obtained from the following three sources:

- Naturally occurring

- Extracted from Limestone and Sandstone

- From Oil Refineries

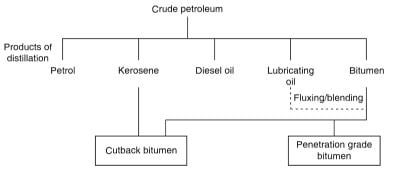

The manufacture of bitumen is a lengthy process which is represented briefly in the below flowchart. The bitumen is a residual material. The final bitumen property will depend upon the extent of extraction, the viscosity, and the distillation process.

The present refinery plant has the capability to extract bitumen more precisely as the required viscosity and consistency.

Safety information:

- Bitumen have been usually flammable and may be kept away from fire or flame.

- Carbon dioxide should be used as a fire suppressant.

- Engineers or workers who work with bitumen ought to use leather gloves, safety eyeglasses and proper clothes and boots when they are operating with hot bitumen.

- The temperature of hot bitumen is around 300 F and it’ll result in severe skin burns and eye injury.

Penetration Test of Bitumen

Penetration test of Bitumen determines the hardness or softness of bitumen by measuring the depth in millimeter to which a standard loaded needle will penetrate vertically in five seconds while the temperature of the bitumen sample is maintained at 25 C.

Also, the Penetration test of bitumen is used to measure the consistency of bitumen.This test is applied almost exclusively to bitumen. For Tars, cutbacks and emulsions other consistency tests are used.

Penetration test on bitumen is carried to determine:

- Consistency of bituminous material

- Suitability of bitumen for use under different climatic conditions and various types of construction.

Importance of Penetration Testing

- The penetration test is used as a measure of consistency. Higher values of penetration indicate softer consistency.

- The test is widely used all over the world for classifying bituminous materials into different grades.

- Depending upon the climatic conditions and type of construction, bitumen of different penetration grade are used. Commonly used grades are 30/40, 60/70 and 80/100.

- In warmer regions, lower penetration grades are preferred and in colder regions bitumen with higher penetration values are used.

- The test is not intended to estimate consistency of softer materials like cut back which are usually graded by viscosity test.

Penetration grade 40-50 is hardest grade and penetration grade 200-300 is softest grade used for cold climates

Penetration Grading

Advantages

- Consistency at average service temperature

- Short testing time

- Adaptable to field applications (contamination)

- Relatively low equipment cost

Disadvantages

- Grade overlap (85-100 grade = AC-5, AC-10, or AC-20)

- Similitude at 77 °F deceptive to

- performance at higher and lower service temperatures

- Rates of test (shear rate) high and variable

- No viscosity available near mixing and compaction temperatures

In different regions and countries, different Standards and Grading systems are used for determining the quality of petroleum bituminous Binders. The most recognized standards for petroleum bitumen are published by

- European Committee for Standardization (CEN)

- Deutsche Industrie Norm (DIN EN)

- Association Française de Normalisation (AFNOR – NF EN)

- BSI Standards – the UK’s National Standards Body (NSB – BS EN)

- American Society for Testing and Materials (ASTM)

- American Association of State Highway and Transportation Officials (AASHTO)

- South African Standard Organization (SABS)

- Standards Australia (AS)

Raha bitumen supplies all Penetration Graded Bitumen Grades in correspondence to ASTM D946-09 and EN 12591-2009, including:

ASTM D946-09 Grades:

- Bitumen Penetration Grade 10/20

- Bitumen Penetration Grade 30/40

- Bitumen Penetration Grade 40-50

- Bitumen Penetration Grade 60-70

- Bitumen Penetration Grade 85-100

- Bitumen Penetration Grade 120-150

- Bitumen Penetration Grade 200-300

EN 12591-2009 Grades:

- Bitumen Penetration Grade 20/30

- Bitumen Penetration Grade 30/45

- Bitumen Penetration Grade 35/50

- Bitumen Penetration Grade 40/60

- Bitumen Penetration Grade 50/70

- Bitumen Penetration Grade 70/100

- Bitumen Penetration Grade 100/150

- Bitumen Penetration Grade 160/220