Australian Standard Bitumen

AS2008 C170, C240, C320, C450 & C600 Grades

Road Construction & Maintenance Applications

Australian Standard Bitumen Classifications

Most high performing roads in Australia are built and maintained using bitumen because it is durable and has exceptional waterproofing and adhesive properties. Bitumens used in road construction and maintenance are refined and blended to meet strict road engineering requirements and industry specifications. Paving grade bitumens are categorized according to viscosity (degree of fluidity) gradings. The higher the grade, the stiffer the bitumen.

RAHA Australian Standard Bitumen Class 170

Class 170 bitumen is widely used in sprayed sealing and light asphalt applications to provide durability and fatigue resistance. It is also used to manufacture cutback bitumens, bitumen emulsions, and modified bitumens.

RAHA Australian Standard Bitumen Class 240

Class 240 bitumen is for use in sprayed sealing applications where the local road agency has a preference for a slightly more viscous bitumen than Class 170.

RAHA Australian Standard Paving Grade Bitumen Class 320

Class 320 bitumen is most commonly used to manufacture asphalt mixes. Due to its higher viscosity, stiffer asphalt mixes can be produced to improve resistance to shoving and other problems associated with higher temperatures and traffic loads.

RAHA Paving Grade Bitumen Class 450

Class 450 bitumen is for use in the manufacture of asphalt mixes where the local road agency has a preference for a slightly more viscous bitumen than Class 320.

RAHA Paving Grade Bitumen Class 600

Class 600 bitumen is primarily used to manufacture extra heavy-duty asphalt pavements that need to endure substantial traffic loadings.

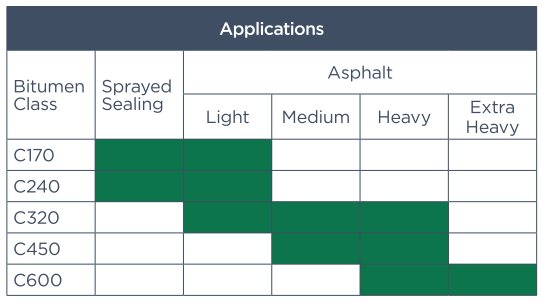

Applications of Australian Standard Paving Grade Bitumen

The table below shows typical applications for paving grade bitumens:

Quality Assurance

RAHA Bitumen is recognized nationally for its proven track record in delivering products of consistently high quality.

Every day our products perform under the most diverse and demanding road conditions in Australia. This is attributable to a combination of our unique product technology, comprehensive quality assurance programs, operational efficiency, and sophisticated production processes – all supported by our highly skilled and experienced staff.

We maintain an in-house national technical center that focuses on R&D, as well as providing technical expertise and support to our customers. Our team of technical specialists is dedicated to ensuring our products are thoroughly tested at every stage – from the selection of crude oil at the start of the production process, right through to delivery.

Our product stewardship and rigorous quality management practices reflect our commitment to delivering the highest quality products that perform on the road. Our commitment to quality is recognized by our accreditation to Australian Standard AS/NZS 9001.

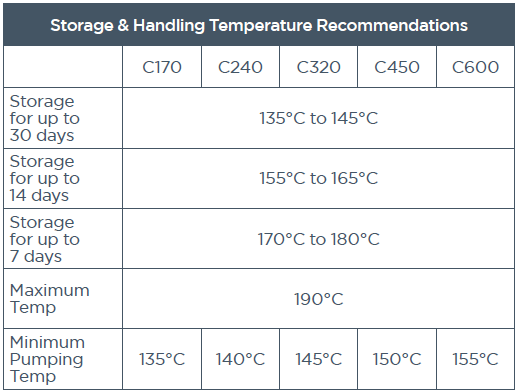

Storage & Handling

The storage of bitumens for prolonged periods at elevated temperatures should be avoided as quality may be adversely affected. As a general rule, bitumen should be stored at the lowest temperature that enables practical use.

For normal operations, such as blending and transferring liquid bitumen, temperatures of 10°C to 40°C above the minimum pumping temperature is recommended.

Health & Safety

To ensure hot bitumen is used in a safe and efficient manner the following safety precautions must be followed:

- Wear suitable personal protective equipment (PPE) at all

times. Full skin protection is required to avoid accidental burns when transferring or handling hot bitumen. - Always prevent contact between water and hot bitumen

by checking the contents of the previous load before loading bituminous products into tankers and by following procedures to avoid violent boil-over of tanks. - Avoid exposure to fumes by standing back on the gantry or upwind until the vapours have dispersed.

- Minimise bitumen fume by heating bitumen and asphalt

products to the recommended temperatures. - Minimise the use of diesel when cleaning equipment as this contributes to the bitumen fume.

For a full description of hazards associated with the use o bitumen, please refer to the appropriate material safety data sheet (MSDS) available on the RAHA Bitumen website.

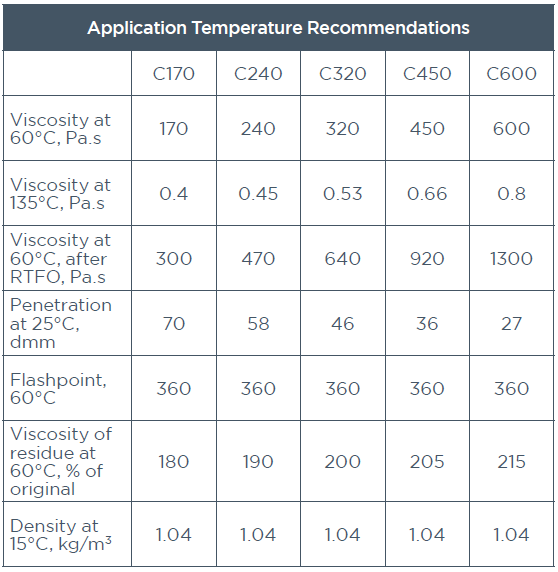

Specification Of Australian Standard Paving Grade Bitumen

RAHA Bitumen Classes 170, 240, 320, 450, and 600 bitumens are manufactured to comply with the requirements of Australian Standard Bitumen AS2008 for pavements.