General Description of Cationic Bitumen Emulsion CRS-2

Bitumen Emulsion CRS-2 is a rapid-setting cationic asphalt emulsion that reacts quickly with aggregate to convert from an emulsion to asphalt. Asphalt emulsions are classified according to the electric charge that surrounds the emulsion’s asphalt particles (i.e. whether it is a cationic or an anionic emulsion) and how quickly the suspended asphalt particles separate from the surrounding water (“breaking”). A rapid-setting emulsion is one that will destabilize quickly when in contact with aggregate. The setting speed of any emulsion is relative to atmospheric conditions at the time of construction.

RAHA Group Bitumen Emulsion CRS-2 is a specially designed water-based Bitumen Emulsion with high viscosity and fast setting that makes it an ideal product for Tack Coat spray application but one of the main applications of CRS emulsion is surface treatment (Chip seal, sand seal, and fog seal by cement curing). CRS-2 is a cationic rapid setting bitumen emulsion that contains 65% bitumen, is black in color, and is manufactured strictly as per ASTM D 2397M-13 standard.

RAHA Group Bitumen Emulsion CRS-2 is a cationic, rapid-setting, bitumen emulsion specifically designed for use in chip sealing. Formulated to break quickly and with a carefully balanced viscosity to minimize run-off, CRS-2 is the ideal binder for use during routine chip sealing.

Application of Bitumen Emulsion CRS-2

RAHA Group Asphalt Emulsion CRS-2 is a cationic, rapid-setting, bitumen emulsion specifically designed for use in chip sealing. Formulated to break quickly and with a carefully balanced viscosity to minimize run-off, CRS-2 is the ideal binder for use during routine chip sealing.

- Maybe sprayed in thicker films due to higher viscosity than CRS-2

- Thicker coatings on aggregates due to CRS-2’s high viscosity leads to increased durability.

- Traffic can be restored very shortly after application.

- Ideal for use in hot temperatures

- No runoff

- Seals narrow cracks against moisture penetration

- Prevents slippage plane between layers

The main application of CRS asphalt emulsion is using for surface treatment projects as:

- Single surface treatment

- Multiple surface treatment

- Sand seal

RAHA Group Bitumen Emulsion CRS2 is ideally suited for surface Dressing, Grouting, and Penetration Macadam.

You will see below more information about applications of this product:

Surface Dressing

It consists of application in one or two coats, each consisting of a layer of bituminous binder sprayed on a previously prepared base, followed by a cover of stone chips rolled in to form a wearing course. RS-2 type cationic bitumen emulsion is ideal for surface dressing on the shoulders and for protection of freshly laid base course. The typical rate of application for two coat surface dressing as per (MORTH&H) clause 510.2 is 28-32 kg/10sq.m.

Grouting

For economical construction of low volume roads, a combined base, and wearing courses can be made by an application of HPCPL CRS-2 cationic bitumen emulsion on the laid and compacted aggregates. This application can be carried out even when the stone layer is damp.

Penetration Macadam

It consists of construction of one or more layer of compacted crushed coarse aggregates with alternate application of bituminous binder and key aggregate. to be used as a base course on road, subject to the requirements of the overall pavement design.

Sand Seal

A bituminous sand application for existing pavement surface to seal the surface and to function as a light-wearing course.

Application Guidelines

- Clean/ prime/ tack pavement surface prior to application.

- Do not apply CRS-2 if precipitation is anticipated.

- Contact with RAHA Marketing representative for application temperature guidelines.

DESIGN GUIDELINES

Designs should be formulated prior to initial production and each time aggregate sources are changed. Testing of the final product is highly recommended to ensure a quality seal. RAHA Technical Services offers complete design services and product quality analysis.

POTHOLE PATCHING

When repairing potholes in pavement, the edges surrounding the pothole being patched should be coated with tack to ensure a bond between the asphalt edge and the patching material. Apply an even coating of CRS-2 to all sides of the hole (approximately 0.20 to 0.25 L/m2 (0.04 to 0.06 gal/yd2)).

SPRAY PATCHING

Spray patching consists of alternate applications of CRS-2 and aggregate to repair deteriorated areas in the pavement surface. Alternating layers of CRS-2 and aggregate may also be used to repair depressions in the road due to rutting or ravelling. Excellent adhesion means longer-lasting repairs.

SINGLE AND MULTIPLE CHIP SEALS

A controlled application of CRS-2 asphalt emulsion to a prepared surface followed by a controlled application of cover aggregate (per lift). Aggregates should be single-sized, washed chip with sizes ranging from 6 mm (¼ in) to 19 mm (¾ in). CRS-2 provides durable, longer-lasting surface treatments with increased resistance to rutting and low-temperature cracking.

Storage and Handling CRS-2

- CRS-2 should be stored in bulk tanks, ideally vertical to minimize surface area

- Do not allow CRS-2 to either freeze or boil: it will break. Safe storage temperatures range from 10°C (50°F) to 85°C (185°F).

- In bulk storage, mix the CRS-2 every 1 to 2 weeks (more frequently in cold weather). Mixing may be done by paddle agitator (slow), loose gear pump, slow centrifugal pump, or another suitable low shear pump.

- Do not bubble air through CRS-2 to agitate it: this creates excessive foam and may cause the CRS-2 to break

- Always use clean storage containers. Make sure prior contents are compatible with CRS-2 or the emulsion may break

- Only use approved and sealed containers for sampling the emulsion.

Advantage of Asphalt Emulsion CRS-2

At the following you can find some advantages of this product:

- No heating required thus eco-friendly

- Cost-efficient

- Easy and even spray

- Low-temperature curing, fast setting time

- High adhesive properties

- Improves pavements service life

- Helps in surface rejuvenation

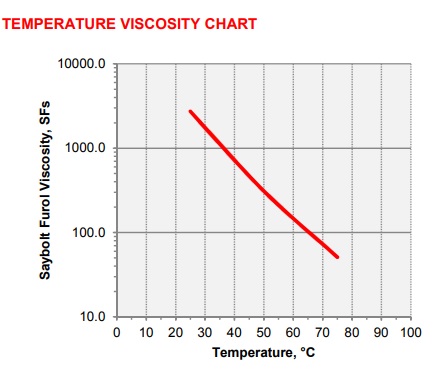

TEMPERATURE VISCOSITY CHART

Packing of Asphalt Emulsion CRS-2

RAHA Group Bitumen Emulsion CRS-2 is available in:

- Bulk as IBC Tank, FlexiTank

- Reconditioned steel drums 220 lit., Net Weight: 200 ± 3 Kg

- New steel drums 220 lit., Net Weight: 200 ± 3 Kg

Product Support

With the RAHA Advantage, you get a partner and advisor who will consult with you about designs, specifications, technical services, processes, and material selection. By developing innovative, custom-designed products that offer additional benefits such as peak performance in unique conditions, improved field performance, and greater environmental and health benefits, the RAHA Advantage provides significant long-term cost savings, resulting in a lower total cost of ownership.

Each lot of CRS-2 is produced using the strictest quality, safety, and environmental guidelines. Each production lot is tested to ensure it meets or exceeds all performance requirements and is delivered with a Certificate of Analysis

Specification of Bitumen Emulsion CRS-2

Emulsion Type: Rapid-Setting

Grade: CRS-2

Standard: ASTM D 2397M – 13

| PropertyProperty | Min | Max | Test Method |

| Test on Emulsions | |||

| Viscosity, Saybolt Furol at 25 °C, SFS | 100 | 400 | ASTM D244 |

| Storage stability test, 24-h, % | – | 1 | ASTM D6930 |

| Demulsibility, 35 mL, 0.8 % dioctyl sodium sulfosuccinate, % | 40 | – | ASTM D6936 |

| Coating ability and water resistance: | |||

| Particle charge test | Positive | ASTM D244 | |

| Sieve test, % | – | 0.1 | ASTM D6933 |

| Distillation : | |||

| Oil distillate, by volume of emulsion, % | – | 3 | ASTM D6997 |

| Residue, % | 65 | – | ASTM D244 |

| Tests on residue from distillation test: | |||

| Penetration, 25°C (77°F), 100 g, 5 s | 100 | 250 | ASTM D5 |

| Ductility, 25°C (77°F), 5 cm/min, cm | 40 | – | ASTM D113 |

| Solubility in trichloroethylene, % | 97.5 | – | ASTM D2042 |