What is Bitumen???

Bitumen, also known as asphalt in the United States, is a substance that forms through the distillation of crude oil. It has waterproofing and adhesive properties. Bitumen production through distillation removes lighter crude oil components, such as gasoline and diesel, leaving the “heavier” bitumen behind. The producer often refines it several times to improve its grade. Bitumen can also occur in nature: Deposits of naturally occurring bitumen form at the bottom of ancient lakes, where prehistoric organisms have since decayed and have been subjected to heat and pressure.

Bitumen is viscous, nonvolatile liquid or solid. Bitumen is a complex colloid system the chemical properties of which are dependent on the properties of crude oil from which it is produced. Pure bitumen is a colloid dispersion of microscopic asphalt particles (dispersion phase). The chemical composition of bitumen is a mixture of various hydrocarbons with molecules of oxygen, sulfur, and nitrogen. Hydrocarbons present in bitumen are mostly condensed naphthene and aromatic rings with the small number of side paraffin chains. Mass fraction of hydrocarbons is 75-85%, hydrogen 9-10%, oxygen 2-8%, sulphur 5-7%, and nitrogen 0.1-0.5%. Bitumen is partially or completely soluble in various organic solvents. Dissolved fractions of bitumen insolvent are called maltenes or petrolenes, and undissolved fractions are called asphaltenes. The maltenes are a mixture of resins and oil, and they are a dispersing agent. For the most part, the physical properties of bitumen depend on the dispersion degree of asphaltenes in maltenes.

Understanding BITUMEN

Bitumen is generally for industry use. Asphalt was first used for its natural adhesive and waterproofing characteristics, but it was also used as a medicine. It was used to bind building materials together, as well as to line the bottoms of ships. ancient civilizations traded the material. Herodotus, a fifth-century BC Greek historian, claimed that the walls of ancient Babylon contained bitumen.

Asphalt is composed of complex hydrocarbons and contains elements such as calcium, iron, sulfur, and oxygen. The quality of material and ease of production depends on the source and type of crude oil it is derived from. The material is used most often in road paving. Most roads in the United States are made of either bitumen or a combination of bitumen and aggregates, such as concrete. Engineers replacing asphalt roads can reuse the material on other road projects. Manufacturers use it in the creation of roofing products due to its waterproofing qualities.

Under heavy loads, Asphalt can deform permanently, depending on the composition of the asphalt mixture, the ambient temperature, and the amount of stress places on the material. Asphalt oxidizes, which can leave the asphalt brittle and result in it cracking.

Properties of Asphalt

- Adhesion: Bitumen has the ability to adhere to a solid surface in a fluid state depending on the nature of the surface. The presence of water on the surface will prevent adhesion.

- Resistance to Water: Bitumen is water-resistant. Under some conditions, water may be absorbed by minute quantities of inorganic salts in the bitumen or filler in it.

- Hardness: To measure the hardness of bitumen, the penetration test is conducted, which measures the depth of penetration in tenths of mm. of a weighted needle in bitumen after a given time, at a known temperature. Commonly a weight of 100 gm is applied for 5 sec at a temperature of 77 °F. The penetration is a measure of hardness. Typical results are 10 for hard coating asphalt, 15 to 40 for roofing asphalt and up to 100 or more for waterproofing bitumen.

- Viscosity and Flow: The viscous or flow properties of bitumen are of importance both at high temperature during processing and application and at low temperature to which bitumen is subjected during service. The flow properties of bitumen vary considerably with temperature and stress conditions. Deterioration, or loss of the desirable properties of bitumen, takes the form of hardening. Resultantly, a decrease in adhesive and flow properties and an increase in the softening point temperature and coefficient of thermal expansion.

- Softening point: Softening point is the temperature at which a steel ball falls a known distance through the bitumen when the test assembly is heated at a known rate. Usually, the test consist of a (3/8)in dia steel ball, weigh 3.5 gm, which is allowed to sink through a (5/8) in dia, (1/4) in the thick disk of bitumen in a brass ring. The whole assembly is heated at a rate of 9 °F per min. Typical values would be 240 °F for coating grade asphalts, 140 °F to 220 °F for roofing asphalt and down to 115 °F for bituminous waterproofing material.

- Ductility: The ductility test is conducted to determine the amount bitumen will stretch at a temperature below its softening point. A briquette having a cross-sectional area of 1 in2 is placed in a tester at 77 °F. Ductility values range from 0 to over 150 depending on the type of bitumen.

USES OF Bitumen

Asphalt is a mixture of dense, sticky, viscous organic liquids, mainly composed of polycyclic aromatic hydrocarbons, naturally occurring or obtained by crude oil distillation.

Naturally occurring or crude bitumen is a sticky, tar-like form of petroleum that is so thick and heavy that it must be heated or diluted before it will flow. At room temperature, it is much like cold molasses. Refined Asphalt is the residual (bottom) fraction obtained by fractional distillation of crude oil. It is the heaviest fraction and the one with the highest boiling point, boiling at 525 °C (977 °F).

In British English, the word ‘Asphalt’ refers to a mixture of mineral aggregate and bitumen (or tarmac in common parlance). The word ‘Tar’ refers to the black viscous material obtained from the destructive distillation of coal and is chemically distinct from bitumen. In American English, Bitumen is referred to as ‘Asphalt’ or ‘Asphalt cement’ in engineering jargon. In Australian English, Bitumen is sometimes used as the generic term for road surfaces. In Canadian English, the word bitumen is used to refer to the vast Canadian deposits of extremely heavy crude oil, while asphalt is used for the oil refinery product used to pave roads and manufacture roof shingles. Diluted Bitumen (diluted with Naphtha to make it flow in pipelines) is known as dilbit in the Canadian Petroleum industry, while bitumen upgraded to synthetic crude oil is known as syncrude and syncrude blended with bitumen as a syn bit

Most bitumens contain sulfur and several heavy metals such as Nickel, Vanadium, Lead, Chromium, Mercury and also Arsenic, Selenium, and other Toxic Elements. Bitumen can provide good preservation of plants and animal fossils.

Bitumen is primarily used for paving roads. Its other uses are Waterproofing Products, including the use of Asphalt in the production of roofing felt and for sealing flat roofs.

Naturally occurring crude bitumen is the prime feed stock for petroleum production from tar sands currently under development in Alberta, Canada. Canada has most of the world’s supply of Natural Asphalt, covering 140,000 square kilometers (an area larger than England), giving it the second-largest proven oil reserves in the world. The Athabasca oil sands are the largest bitumen deposit in Canada and the only one accessible to surface mining, although recent technological breakthroughs have resulted in deeper deposits becoming producible by in-situ methods. Because of oil price increases since 2003, upgrading bitumen to synthetic crude oil has become highly profitable. As of 2006 Canadian crude bitumen production averaged about 1.1 million barrels (170,000 m3) per day and was projected to rise to 4.4 million barrels (700,000 m3) per day by 2020. The total amount of crude Asphalt in Alberta which could be extracted is estimated to be about 310 billion barrels (50×109 m3), which at a rate of 4.4 million barrels per day would last about 200 years.

In the past, Asphalt was used to Waterproof Boats, and even as a coating for buildings with some additives. The Greek historian Herodotus said hot Asphalt was used as a mortar in the walls of Babylon. It is also possible that the city of Carthage was easily burnt due to the extensive use of Asphalt in construction.

Vessels for the heating of Asphalt or bituminous compounds are usually subject to specific conditions in public liability insurance policies, similar to those required for blow torches, welders, and flame-cutting equipment.

Asphalt was also used in early photographic technology. It was most notably used by French scientist Joseph Nicéphore Niépce in the first picture ever taken. The Asphalt used in his experiments was smeared on pewter plates and then exposed to light, thus making a black and white image.

Thin Asphalt plates are sometimes used by computer enthusiasts for silencing computer cases or noisy computer parts such as the hard drive. Asphalt layers are baked onto the outside of high-end dishwashers to provide sound insulation.

Geologic origin

Naturally occurring deposits of Asphalt are formed from the remains of ancient, microscopic algae and other once-living things. These organisms died and their remains were deposited in the mud on the bottom of the ocean or lake where they lived. Under the heat and pressure of burial deep in the earth, the remains were transformed into materials such as Asphalt, kerogen, or petroleum. As bitumens are also found in meteorites and Archean rocks it is possible that some bitumens are primordial material formed during accretion of the Earth and reworked by bacteria that consume hydrocarbons. Bitumens are associated with lead-zinc mineralizations in Mississippi Valley-type deposits.

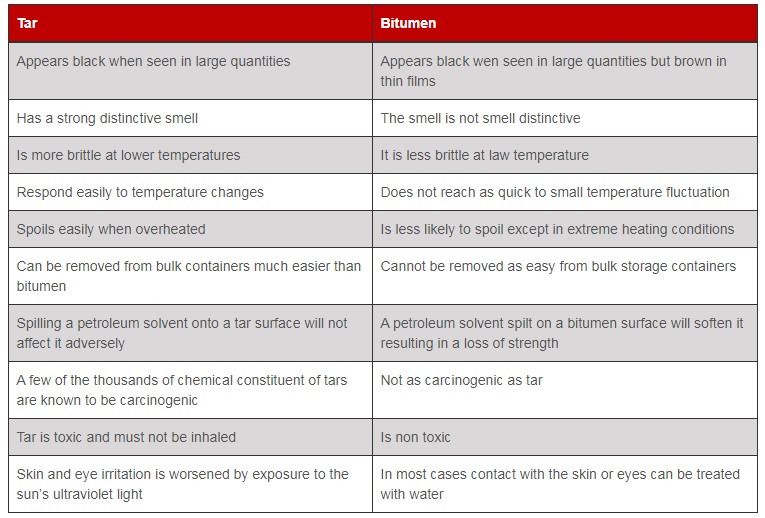

Tar and Natural bitumen

Petroleum Asphalt is often confused with tar. Although Asphalt and coal tar are similarly black and sticky, they are distinctly different substances in origin, chemical composition and in their properties. Coal tar is produced by heating coal to extremely high temperatures and is a by-product of gas and coke production. It was widely used as the binding agent in road asphalt in the early part of the last century but has since been replaced by refined Asphalt. Tar sands, also called oil sands, are deposits of a mixture of fine clay, sand, water, and variable amounts of Asphalt which is a black, high-sulfur, tar-like, heavy oil. Tar sands are sedimentary rocks and the Asphalt is an asphaltic substance. Typical tar sand is composed of approximately 83% sand, 13% Asphalt, and 4% water (by weight percent). Tar sands containing more than 6% by weight of Asphalt are considered to have commercial potential. The difference between oil shale and tar sand is that the bituminous matter in shale is solid, whereas, the bituminous matter in tar sand is a highly viscous liquid. Oil which is particularly thick and viscous is called heavy oil, or more colloquially, tar or asphalt.

Naturally-occurring bitumen, sometimes also called natural asphalt, rock asphalt, lake asphalt or oil sand, has been used as an adhesive, sealant and waterproofing agent for over 8,000 years. But it occurs only in small quantities and its properties are quite different from refined bitumen.