Roofing Asphalt

How to Make Roofing Asphalt

Let’s start at the very beginning

According to Julie Andrews it is a very good place to start. Roofing asphalts are made by first starting with a flux – a low-viscosity asphalt – and then subjecting the flux to an oxidation process to achieve the desired properties. Typical asphalt fluxes used for roofing manufacturing would be characterized as an AC-2.5 or PG 46-xx material in paving terms. Without additional processing these asphalts would be too soft for typical paving applications.

It is not unusual for a manufacturer to use blends of fluxes to get the desired properties after processing. Sometimes blends are used to upgrade a flux that is considered by the manufacturer to have less than optimal physical or chemical properties. Other times, blends are used because of availability. Additives and catalysts – such as polyphosphoric acid (PPA) and ferric or ferrous salts – may also be used during the oxidation process to help the finished product reach its desired set of properties.

Roofing Asphalt, Oxidation (air blowing)

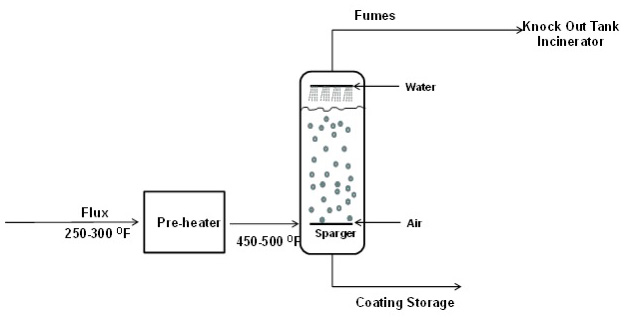

Once the formulation of the material has been selected, the blend is ready to go through the oxidation, or air blowing, process. Air blowing is the process of passing air through heated asphalt to raise the softening point of the asphalt while maintaining much of its flexibility at lower temperatures. In a conventional batch oxidation process, the flux enters a pre-heater at approximately 121-149°C (250-300°F) and is heated to and maintained at 232-260°C (450-500°F) entering the oxidation still. There it stays, with air bubbling through it for several hours, until the softening point has been raised to approximately 100- 105°C (212-220°F) and the penetration value has dropped into the range of 15-23 dmm at 25°C (77°F). The conventional batch oxidation process is shown in Figure 1. The continuous oxidation process is similar except that the product moves from one still to the next during oxidation until the product has reached its desired properties.

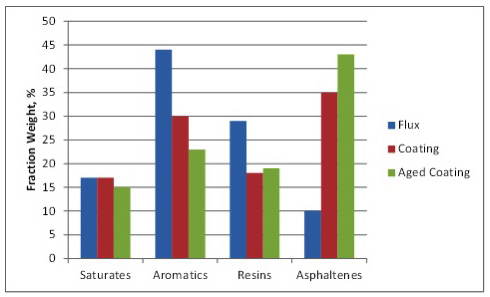

Asphalt oxidation is a complex controlled exothermic reaction process involving the reaction and rearrangement of asphalt molecules in the presence of oxygen at elevated temperatures (such as in a blow still or rooftop). The process includes dehydrogenation, aromatization, oxygen uptake, and a loss of volatile material. The average molecular size of the asphalt molecules increases as the components of asphalt – generally referred to as SARA fractions – change proportions. Saturates (paraffins, waxes designated as “S”) change very little as they are fairly unreactive. Aromatics (naphthene aromatic rings designated as “A”) change to Resins (polar aromatic rings designated as “R”) which, in turn, change to Asphaltenes (large, polar aromatic rings) during oxidation. Changes in the SARA fractions as a result of oxidation are shown in Figure 2. Note that the aged coating exhibits additional oxidation in the form of reduced aromatics and increased asphaltenes compared to the coating.

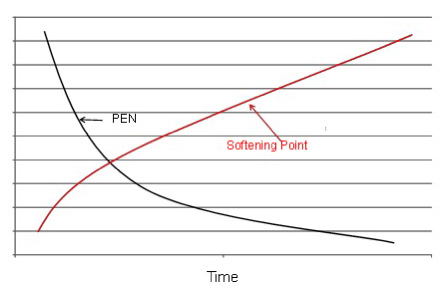

The oxidation process and conversion of aromatic components to asphaltenes causes the softening point and viscosity to increase and the penetration to decrease as the time in the oxidation still increases (Figure 3 below.)

Not all oxidation processes are the same as there are several parameters that can have an effect on the final oxidized product. The size of the oxidation still, specifically the height/diameter ratio, is important to control the surface area of the air bubbles. The size of the air bubbles can be affected by the sparger size. Smaller bubbles have an increased surface area, allowing for more reaction. Likewise, the volume of air flow controls the residence time of the bubbles which affects the reaction.

Like everything else asphalt-related, temperature is a key parameter. While the oxidation process typically occurs around 260°C (500°F), the temperature can be increased to reduce the oxidation time and harden the final product (coating) by increasing the softening point/penetration ratio. Conversely, decreasing the temperature will increase the oxidation time and soften the final product (coating) by decreasing the softening point/ penetration ratio. Either technique may be employed by the manufacturer depending on the specific properties of the flux, or blend of fluxes, being used.

For safety reasons it is important to remember that during the oxidation process the asphalt should not be heated to an elevated temperature that approaches its flash point. As a matter of caution, the oxidation temperature that is used should be at least 28°C (50°F) lower than the flash point (Cleveland Open Cup or COC) of the asphalt being oxidized.

Finally, catalysts like ferric and ferrous salts may be used to impact the oxidation process and affect the properties of the finished product. The use of these catalysts may improve the flexibility and weathering resistance and increase the penetration value for a specific softening point, but the improvement in properties is very much crude-dependent. Special handling and control equipment is needed when using these catalysts. Although not considered a “true” catalyst, polyphosphoric acid (PPA) may also be used to a similar effect as the ferric and ferrous salts.

Roofing Asphalt, The end game

The final chemical and physical properties of a roofing asphalt is dependent on a number of things including the source (or sources) of flux used, the addition of any catalysts, and the oxidation process to name a few. A manufacturer needs to understand the impacts that all of these factors, and more, have on physical properties like resistance to flow, flexibility, and resistance to weathering. That knowledge is what gives the customer the confidence to use asphalt shingles and expect that they’ll perform.

Putting roofing asphalt to the test

To reset the stage, the roofing market is divided into two general categories: steep-slope and low-slope.

Steep-slope roofing includes coverings installed on slopes exceeding 14 degrees. This is usually associated with residential roofing and, by connection, shingles. Low-slope roofing includes water-impermeable or weatherproof systems installed in slopes that are less than or equal to 14 degrees. This is usually associated with commercial roofing systems.

Standard specifications for asphalt shingles can be found through the American Society for Testing and Materials (ASTM) in ASTM Standard D3462 “Standard Specification for Asphalt Shingles Made from Glass Felt and Surfaced with Mineral Granules.” Although a number of properties are listed in the specification, only two properties are specifically related to the coating asphalt used in the shingle manufacture: penetration at 77°F (25°C) and softening point (ring and ball).

These two properties provide some general indication of the consistency (stiffness) of the asphalt at intermediate and high temperatures, but don’t tell the whole story about whether or not a particular asphalt will make a good shingle coating.

Properties of good roofing asphalt for steep-slope applications

What kind of properties does a good roofing asphalt need? For shingles, a roofing asphalt must have the following properties:

- resistance to flow at high temperatures,

- proper adhesion (neither overly sticky or brittle) for mineral granules,

- resistance to water intrusion (waterproof),

- resistance to fire (fire retardant),

- proper tensile strength, flexibility and

- low potential for staining.

These properties can be affected by the crude source and process used to produce the roofing asphalt flux before it is oxidized into a roofing asphalt.

Resistance to flow at high temperature

Resistance to flow at high temperatures means that the roofing asphalt used in the shingle should be stiff enough at the temperatures encountered on the roof that it won’t slough off of the shingle. Depending on the geographical area in which it is used, an asphalt roofing material could experience temperatures as high as 80°C (176°F).

For roofing asphalt, resistance to flow has been most often characterized through the use of the softening point test – usually the Ring & Ball Softening Point test (ASTM D36). In this test, an asphalt sample is poured into two small brass rings, trimmed, and loaded with a steel ball in the center of each ring. After the samples are prepared, the assembly is suspended in a beaker of water, glycerin or ethylene glycol at a height of 25 millimeters (1 inch) above a metal plate. The liquid is then heated at a rate of 5°C (9°F) per minute. As the asphalt softens, the balls and the asphalt gradually sink toward the plate. At the moment the asphalt ball touches the plate, the temperature of the liquid is determined, and this is designated as the ring-and-ball (R&B) softening point of the asphalt binder sample.

It is important to note that for asphalt materials, the softening point is not the same thing as the melting point. Asphalts do not have an exact melting point since they are neither crystalline nor chemically homogeneous. As such, the softening point is simply an arbitrary indication of the resistance to flow at rooftop temperatures.

Typically, unmodified paving grade asphalt binders will have softening point temperatures in the range of approximately 35-55°C (95-130°F) depending on the grade of the asphalt binder. A modified paving grade asphalt binder could have softening point temperatures in the range of approximately 50-75°C (122-167°F) – again, depending on the grade of the modified asphalt binder as well as the type of modification. Roofing asphalt binders, particularly those used for shingle coating, typically have softening point temperatures in the range of approximately 88-105°C (190-221°F).

Proper adhesion characteristics

In addition to resistance to flow at high temperatures, a roofing asphalt should have proper adhesion characteristics so that granules will stick to the shingle without it being overly sticky (at high temperatures) or brittle (at intermediate-low temperatures). This characteristic has typically been measured by using the penetration test (ASTM D5) at three temperatures: 4, 25 and 46°C (41, 77, and 115°F).

To conduct the penetration test, an asphalt sample is heated to an appropriate pouring temperature and poured into a test container — usually a 3-ounce tin. After a specified conditioning period which is tightly controlled to minimize the effects of steric hardening, the asphalt sample is brought to 25°C (77°F) in a temperature-controlled water bath. The sample container is then placed in the penetrometer equipment. A needle of prescribed dimensions is attached to the penetrometer and suspended directly over the asphalt binder sample. A 50-gram weight is attached to the needle’s loading platform so that the total weight used for loading is 100 grams (50-gram weight plus the needle assembly weight of 50 grams). The penetrometer is lowered until the needle tip just contacts the surface of the asphalt. The load is then released, allowing the weighted needle to penetrate the asphalt for 5 seconds. The distance that the needle penetrates into the asphalt is reported as the penetration value. This distance is reported in units of 0.1 millimeters, or decimillimeters (dmm).

Roofing technologists have found that penetration values for shingle coating asphalt should be in the range of 16-22 dmm to provide good adhesion characteristics while not being overly sticky or brittle. The penetration test provides an empirical measure of the consistency of the roofing asphalt binder at moderate temperatures.

Resistance to water intrusion (waterproof)

By its nature, asphalt is a waterproofing material. No standard tests are used to validate this property.

Resistance to fire (fire retardant)

As a petroleum product, an asphalt will release combustible fumes when heated to sufficiently high temperatures. The flash point provides an indication of the temperature at which a heated asphalt sample will instantaneously flash in the presence of an open flame. It is important to note that this temperature is usually well below the temperature at which the material will support combustion. The temperature at which the material supports combustion is called the fire point. It is rarely if ever, used in asphalt specifications.

The most common test method used to determine the flash point of an asphalt is the Cleveland Open Cup (COC) flash point test. In this test, a brass cup is first filled with a specified volume of asphalt and is heated at a constant rate. A small flame is passed over the surface of the asphalt at timed intervals. When the flame passing over the sample surface causes an instantaneous flash, the temperature is recorded as the material’s flash point.

The purpose of the flash point test is to measure the tendency of the asphalt to produce flammable vapors when heated under controlled laboratory conditions. As stated in the test method, it (flash point) shall not be used to appraise the risk of a fire hazard, but instead shall be one component in an overall strategy for fire risk management. The results of the test method are related to safety, and not the quality of the asphalt.

To produce roofing asphalt, it is important to recognize that the oxidation process typically occurs at 260°C (500°F). As such, asphalts that will be oxidized to produce roofing asphalt products should have a minimum flash point of 260°C (500°F) in order to safely conduct the oxidation process.

Proper tensile strength

Shingles are required to have a minimum tear strength as described in ASTM D3462 “Standard Specification for Asphalt Shingles Made from Glass Felt and Surfaced with Mineral Granules.” The roofing asphalt provides some assistance in meeting this requirement by being sufficiently flexible so the shingle can be handled at extreme temperatures without cracking or deforming. The ductility test (ASTM D113) provides a method that can be used for empirically determining the ductility of an asphalt at 25°C (77°F).

Low potential for staining

Shingle staining occurs in service when the lighter oils in the roofing asphalt transfer from the shingle coating to the granule surface. This phenomenon also referred to as “tobacco juicing”, can happen during the initial weathering period of the shingle when in service. The exudation of oils onto the granule surface likely doesn’t have a significant impact on the long-term performance of the shingle, but it can result in an unaesthetic appearance on the roof.

Staining tendency can be determined by using ASTM D2746, Standard Test Method for Staining Tendency of Asphalt (Stain Index). In this test, roofing asphalt is poured into a brass ring with an inside diameter of 16-mm placed on a sheet of filter paper supported by a brass plate. The sample is then heated at 80°C (175°F) for 120 hours. The diameter of the resulting stained circle on the filter paper is then compared to the inside diameter of the brass ring to determine the stain index – calculated as the difference between the diameter of the stained circle and the inside diameter of the brass ring, expressed in 0.4-mm increments (oddly enough, but thanks to the conversion from inches to millimeters). Regardless of the odd units, a higher stain index indicates lower thermal stability and greater tendency for staining. Generally speaking, a stain index less than 10 indicates low staining tendency while a value greater than 20 indicates a high staining tendency.

Resistance to weathering

A good roofing asphalt must also have sufficient resistance to weathering so that the shingle can remain durable for many years in service. Most roofing technologists classify the weathering ability of a roofing asphalt by using one of two weatherometer test procedures (described in ASTM D4798 and D4799). Unfortunately, the weatherometer test, which mimics thermal and UV aging of an asphalt shingle, can take 2,000-3,000 hours of continuous operation (or approximately 83-125 days) to characterize the weathering ability of a roofing asphalt.