Iran Foots Oil

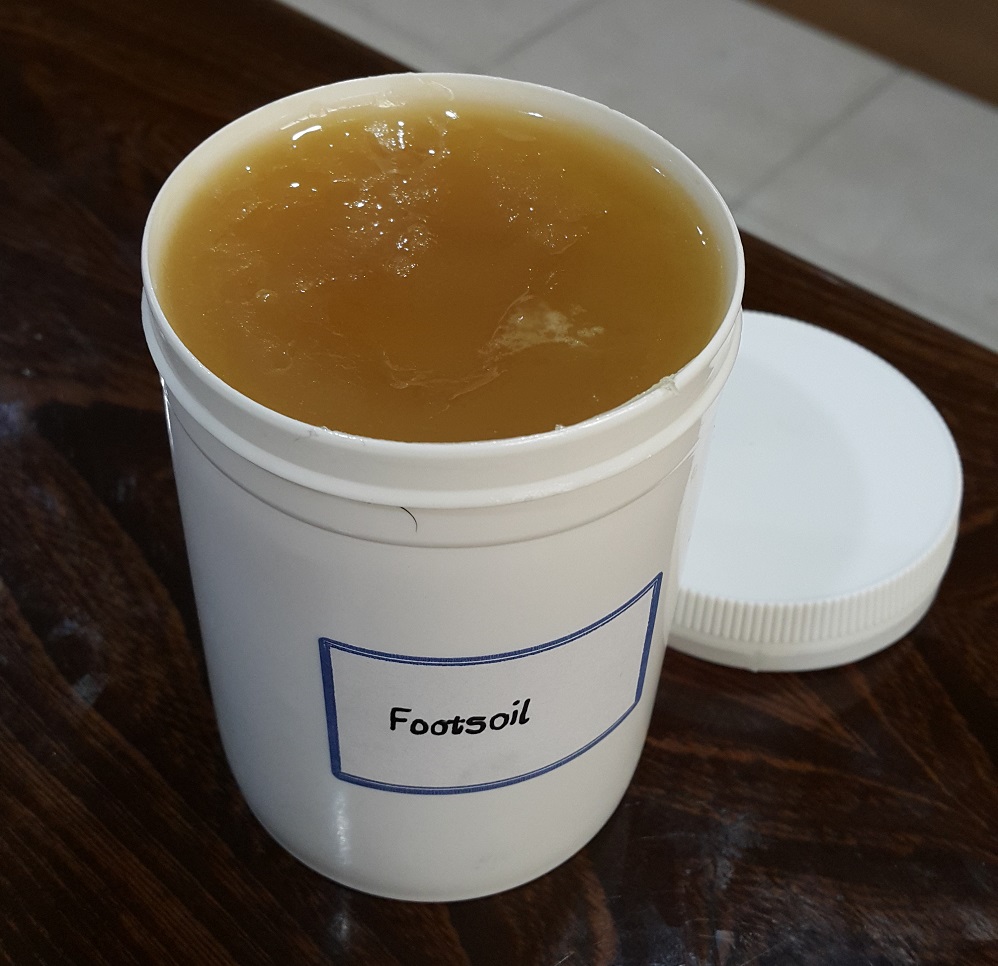

residue wax (Foots Oil)

Residue Wax Definition

residue wax or Foots oil, is a by product obtained by slack wax deoiling or sweating in the paraffin wax manufacturing process. It is used in textile, leather and rubber industries, as well as petroleum jelly and white oil manufacturing.

Residue wax is the mixture of oil and slack wax. This wax, formally known as Foots oil is a commodity derived from the production of semi refined paraffin wax, having almost 60% result from 100% of slacks provided by the oil refineries.

Application of Residue Wax

Foots oil is used in the following products:

adhesives and sealants, anti-freeze products, coating products, fillers, putties, plasters, modelling clay, finger paints, fertilisers, fuels, non-metal-surface treatment products, inks and toners, leather treatment products, lubricants and greases, plant protection products, polishes and waxes and textile treatment products and dyes.

Other release to the environment of this substance is likely to occur from: indoor use as processing aid, outdoor use as processing aid, indoor use in close systems with minimal release (e.g. cooling liquids in refrigerators, oil-based electric heaters) and outdoor use in close systems with minimal release (e.g. hydraulic liquids in automotive suspension, lubricants in motor oil and break fluids).

Main Application

-

Adhesives & sealants

-

Lubricants, greases & metalworking fluids

-

Textile, leather & rubber treatments

-

Wood/plywood processing (polishes, modeling compounds)

-

Coatings & inks

-

Agricultural formulations (plant protection agents)

-

Pastes, fillers, putties, modelling clays

-

Antifreeze & fuel brick components

Packing of Residue Wax

Foots oil is packed in new steel drums commonly, but for decrease the cost we can use reconditioned or second hand drum instead of the new one. As the foots oil is not a cosmetic or pharma grade material such as petroleum jelly, we can use second hand drums for packing.

ISO tank and flexitank are not used for foots oil because it is a waxy material with 40 to 50% oil and also it is not economic to use these luxury packing for this wax.

Analysis of Residue Wax

Foots oil has a general analysis that you can find in the below. To having the exact analysis of each part please contact our sales team.

| Residue wax | |||||

| Typical characteristics foots oil grade | Oil content %wt max. | Congealing point C | Color max | Viscosity & 100 C (cSt) | Color |

| ASTM D-721 | ASTM D-938 | ASTM D-445 | ASTM D-445 | ASTM D-1500 | |

| Light | 25-40 | 40 | 3.9 | 3.6-4.6 | 1.5 |

| Medium | 25-50 | 25 | 3.8-4.4 | 4.7-6.9 | 2 |

| Heavy | 25-50 | 25 | 4.5-6.5 | 7-11.5 | 2.5 |

Supplier of residue wax

RAHA Oil Co. is a residue wax supplier Across world, We supply high-quality residue wax, tailored to meet the needs of various industries. we can deliver the mentioned Wax types to destination ports as requested by the customer. However, our team will assist at every step to ensure a smooth and timely supply. (Contact Us)