Introduction Steel Rebar

Steel rebar, short for reinforcing bar, is the backbone of modern construction. From skyscrapers and bridges to residential foundations, rebar provides the tensile strength that concrete alone cannot. As global infrastructure continues to expand, the demand for high-quality steel reinforcement materials is stronger than ever.

Importance in Import and Export of Rebars

Steel rebar is a critical commodity in the global market. Its import and export play a vital role in meeting the demand for infrastructure development worldwide. Countries with robust steel industries export high-quality rebar, while others rely on imports to support their construction projects.

At RAHA Group, we specialize in the import and export of premium-grade steel rebar, serving clients across Asia, the Middle East, Africa, and Europe. With strict adherence to international standards and a reputation for reliability, we are your trusted partner in global steel supply.

Why Choose Our Steel Rebar?

- High Strength and Durability: Manufactured from high-quality billet steel for maximum performance and longevity.

- Global Standards Compliance: Available in ASTM, BS, and other international grades and specifications.

- Flexible Supply Options: We handle both bulk shipments and customized orders, ensuring fast delivery worldwide.

- Competitive Pricing: Through direct relationships with trusted mills and efficient logistics, we deliver cost-effective solutions without compromising quality.

- Proven Export Expertise: Our export team ensures smooth customs clearance, documentation, and logistics for every shipment.

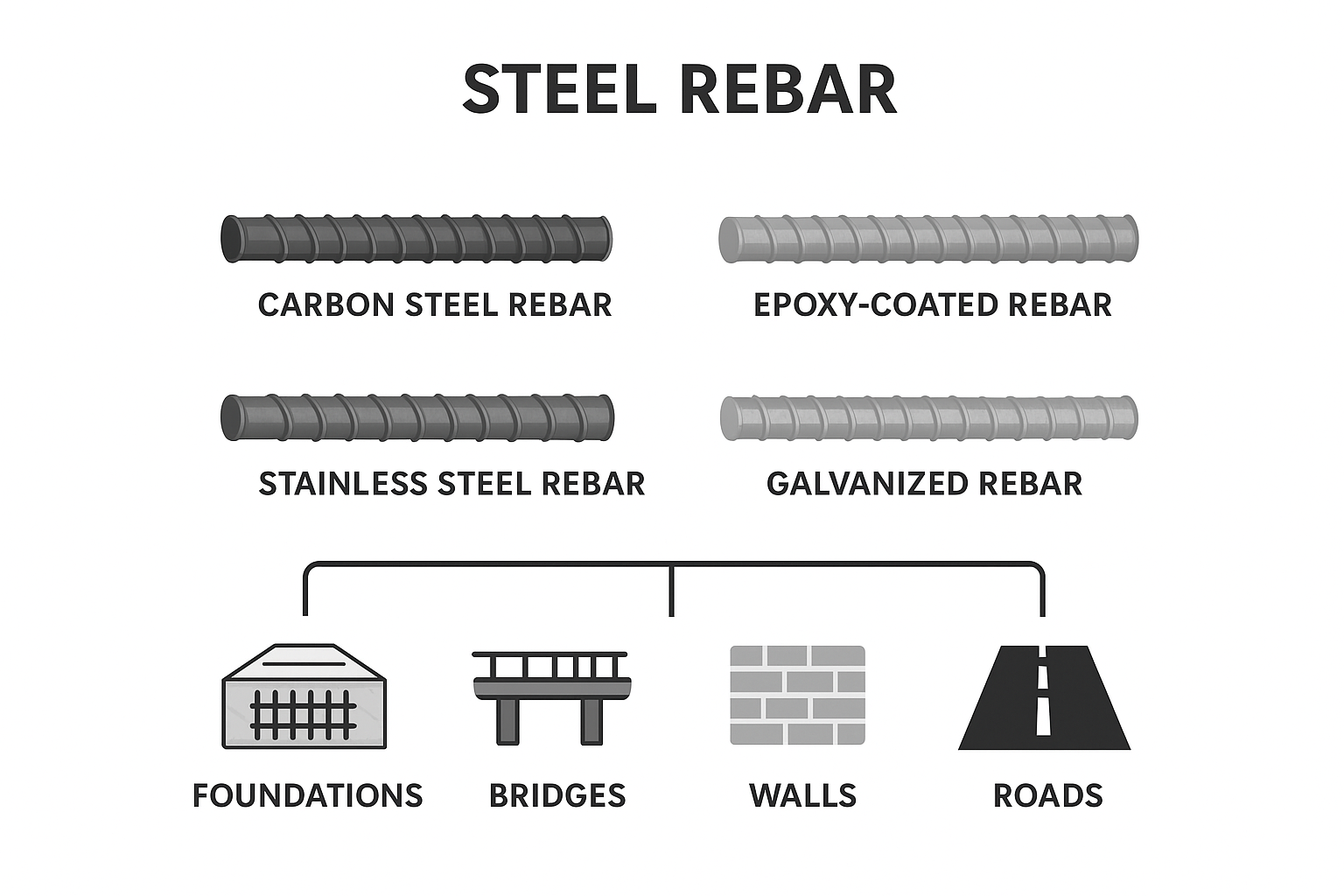

| Rebar Type | Description | Key Advantage | Typical Use |

|---|---|---|---|

| Carbon Steel Rebar (Black Bar) | The most common and least expensive type. | High tensile strength | General-purpose construction (roads, buildings, bridges). |

| Epoxy-Coated Rebar | Standard black bar coated with an epoxy resin to resist corrosion. | Excellent for saltwater and high-humidity environments. | Bridge decks, marine structures. |

| Galvanized Rebar | Coated with a layer of zinc for corrosion resistance, offering better damage tolerance than epoxy. | Superior resistance to wear and tear during handling. | Areas with moderate to high moisture. |

| Stainless Steel Rebar | Highly resistant to corrosion; an excellent long-term solution. | Ultimate corrosion resistance and very long service life. | High-cost, high-profile, or long-life infrastructure (tunnels, monuments). |

| Glass Fiber Reinforced Polymer (GFRP) Rebar | Non-metallic rebar, used in specialized applications. | Non-conductive and completely non-corrosive. | Magnetic Resonance Imaging (MRI) rooms, specialized scientific labs. |

Current Trends of Rebar Steels

As of October 2025, the demand for steel rebar continues to rise due to ongoing global infrastructure projects. Sustainable production methods and recycled steel are becoming increasingly popular in the industry.

Valued at approximately USD 259 billion in 2024, the market is projected to reach USD 250-260 billion in 2025, with forecasts indicating expansion to USD 337-419 billion by 2033 at a CAGR ranging from 3.8% to 5.3%. This growth is primarily driven by urbanization, government-backed projects, and a shift toward sustainable practices. Below, we break down the key trends based on recent market analyses and real-time discussions.

Market Growth and Demand Drivers

Infrastructure Boom: The surge in public infrastructure spending remains the dominant force. Globally, projects like India’s National Infrastructure Pipeline (INR 111 lakh crore through 2025) and the U.S. expansion of highways and renewable energy facilities are fueling demand. Public infrastructure accounts for over 61% of rebar usage, expected to hit USD 144.7 billion by 2034.

Regional Dominance: Asia-Pacific holds the largest share (over 50% in 2025), led by China and India, where construction in resilient, earthquake-resistant structures is prioritized. China’s building sector offsets industrial slowdowns, maintaining high consumption levels.

Volume Projections: Global rebar volume is forecasted to reach 144.75 million tons in 2025, growing at 5.74% CAGR to 191.34 million tons by 2030, with deformed rebar dominating due to its superior bonding in concrete.

Price Volatility and Trade Influences

Current Pricing: Steel prices dipped to 3,005 CNY/T on October 1, 2025, down 0.89% daily and 10.83% year-over-year, reflecting softer demand and oversupply. In India, the HRC-rebar spread widened in September 2025 (HRC at ₹49,200/tonne vs. rebar at ₹47,100/tonne), influenced by policy shifts like export duties and anti-dumping measures.

Regional Variations: Q2 2025 prices showed mixed trends—China at 468 USD/MT (down due to U.S.-China trade tensions), Brazil at 833 USD/MT, Germany at 873 USD/MT, and the U.S. at 863 USD/MT. Elevated U.S. import tariffs on carbon steel in early 2025 have disrupted supply chains, boosting domestic production but increasing costs.

Trade Shifts: Exports peaked in 2021 but declined with duties; 2023 saw record HRC imports. Ongoing U.S. tariffs and global port congestions continue to create volatility.

Technological and Product Innovations

Shift to Deformed and High-Strength Rebar: Deformed rebar (with ridges for better grip) led with USD 115.1 billion in 2024 and is growing at 4.4% CAGR through 2034, promoted for its ductility and tension resistance. Mild steel’s share is declining as governments mandate high-strength variants for safety.

Coatings for Durability: Epoxy-coated and galvanized rebars are gaining traction in corrosive environments like coastal areas, while stainless steel variants are used in high-corrosion zones.

Manufacturing Advances: Thermo-mechanical treatments enhance rebar quality, and processes like Basic Oxygen Steelmaking dominate for large-scale production.

Sustainability and Challenges

Green Initiatives: A notable trend is the rise of recycled and low-carbon rebar, aligning with global net-zero goals. Renewable energy projects (e.g., wind farms) are increasing demand for eco-friendly reinforcements.

Types of Steel Rebar We Supply

We offer a full range of rebar types suitable for various construction applications:

- Carbon Steel Rebar – The most common and economical option for general construction.

- Epoxy-Coated Rebar – Ideal for environments exposed to moisture and corrosion.

- Stainless Steel Rebar – Used in marine and chemical environments where superior corrosion resistance is required.

- Galvanized Rebar – Protected with a zinc coating for enhanced lifespan.

- GFRP (Glass Fiber Reinforced Polymer) Rebar – Lightweight and non-corrosive alternative for specialized projects.

Grades and Sizes

Our rebar is available in a wide range of diameters and grades to meet your project requirements:

Grades: ASTM A615 (Grade 40, 60, 75), BS4449 (Grade 250, 460), and others upon request.

Sizes: From 6mm to 50mm diameter, available in standard or custom lengths.

Packaging: Bundled, tagged, and export-ready with mill certificates included.

Applications of Rebar Steel

Steel rebar from RAHA GROUP is trusted for use in:

Residential, commercial, and industrial construction

Bridges, highways, and tunnels

Ports, dams, and marine structures

Oil & gas and energy infrastructure projects

Global Reach

With an extensive distribution network, we export steel rebar to major markets including:

Asia: UAE, Saudi Arabia, India, Singapore

Africa: Nigeria, Kenya, Egypt, South Africa

Europe & Americas: United Kingdom, Spain, Brazil, Chile

We coordinate with reliable freight and logistics partners to ensure timely and cost-efficient delivery to your port of destination.