Introduction of Steel Rebars

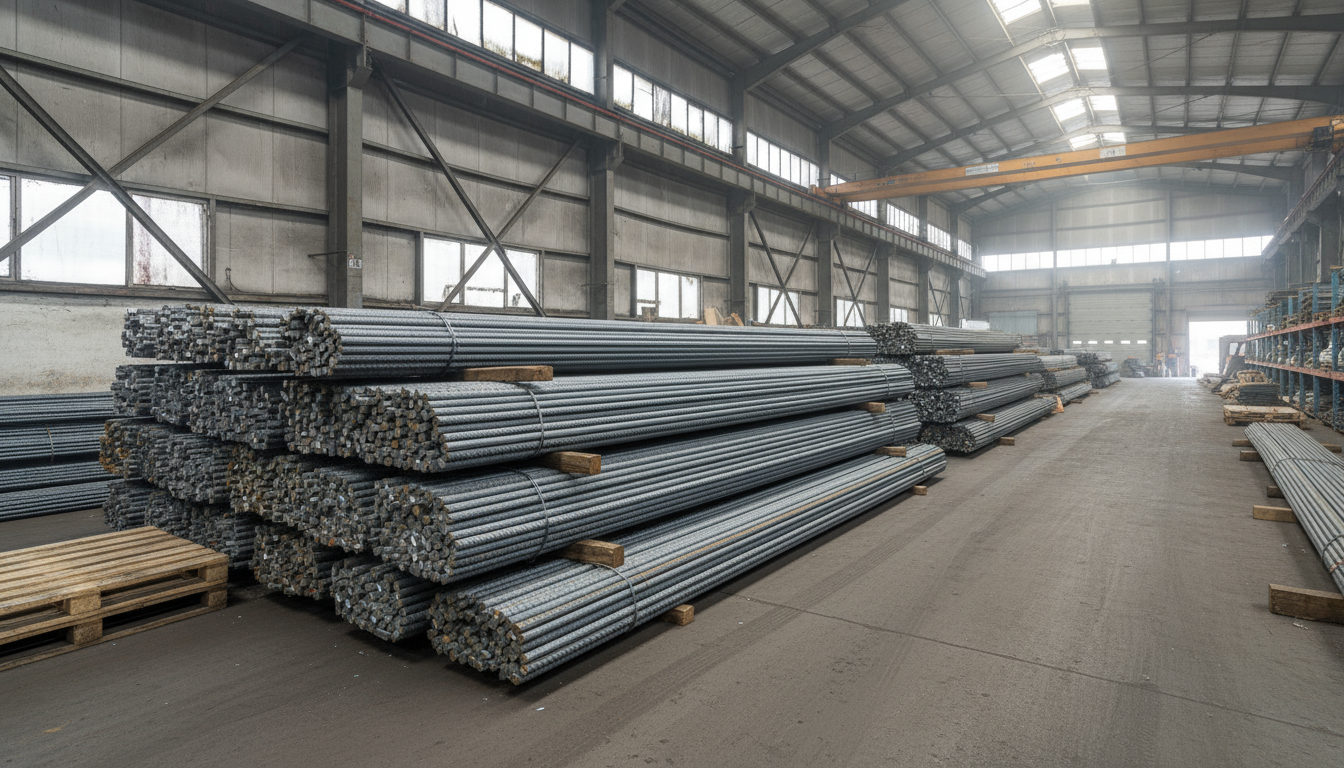

In the fast-growing world of infrastructure and construction, Manufacturer of Steel Rebars (reinforcing bars) play a crucial role in giving concrete the tensile strength it needs to withstand stress, temperature, and load.

Different Fields

Behind every durable bridge, skyscraper, or tunnel lies the strength of well-engineered rebar — and few names stand out in this field like RAHA GROUP, a global manufacturer and supplier of steel rebars trusted by construction professionals across the world.

With years of expertise, advanced manufacturing technology, and a strong commitment to quality, RAHA GROUP delivers steel rebars that meet and exceed international standards — ensuring safety, reliability, and performance for projects of all scales.

Why Steel Rebars Are Essential

In contrast to its impressive strength under compression, concrete is weak under tension, which is why it requires reinforcement with steel rebars. Rebars bridge that gap by reinforcing concrete and giving it the flexibility and tensile strength needed to handle dynamic loads. They help prevent cracking, increase lifespan, and improve overall structural integrity.

Key benefits of steel rebars include

- Enhanced Structural Strength – Adds tensile power to concrete structures.

- Durability – Resistant to stress, vibration, and temperature changes.

- Flexibility – Suitable for all types of construction, from homes to mega infrastructure.

- Cost-Effectiveness – Long lifespan reduces maintenance and repair costs.

leader manufacture and global supply of steel rebars

RAHA GROUP has established itself in the Manufacturer of Steel Rebars, backed by modern production facilities and a dedicated engineering team. The company operates with a focus on precision, consistency, and innovation, ensuring each product meets the highest technical and performance standards.

Manufacturing Excellence

rebar production process integrates state-of-the-art rolling mills, automated quality testing, and strict metallurgical control to produce rebars that comply with international specifications such as ASTM A615, BS4449, and ISO 6935.

Each batch is tested for

- Tensile and yield strength

- Bend and rebend performance

- Chemical composition and purity

- Dimensional accuracy and rib pattern integrity

Steel Rebar Sizes and Common Construction Uses

| Diameter (mm) | Nominal Area (mm²) | Weight (kg/m) | Typical Applications |

|---|---|---|---|

| 9.5 mm | 71 mm² | 0.560 | Light construction, driveways, patios, small slabs |

| 12.7 mm | 129 mm² | 0.994 | Residential foundations, footings, walls |

| 15.9 mm | 199 mm² | 1.552 | Beams, columns, bridge decks |

| 19.1 mm | 284 mm² | 2.235 | Heavy foundations, retaining walls, industrial floors |

| 22.2 mm | 387 mm² | 3.042 | High-rise structures, reinforced columns |

| 25.4 mm | 510 mm² | 3.973 | Bridges, large concrete structures |

| 28.7 mm | 645 mm² | 5.042 | Dams, heavy civil infrastructure |

| 32.3 mm | 819 mm² | 6.404 | Tunnels, marine and high-load projects |

| 35.8 mm | 1006 mm² | 7.907 | Industrial foundations, high-strength applications |

Most Common Rebar Sizes in Construction

The (12 mm) and (16 mm) rebars are the most widely used in residential and commercial construction, particularly for slabs, beams, and columns. They offer a balance between strength, flexibility, and ease of handling.

Global Supply and Export Services

As an international steel rebar manufacturer and exporter, RAHA GROUP proudly serves clients across the Middle East, Africa, Asia, and Europe.

The company’s logistics network ensures:

Fast and reliable delivery

Export-ready packaging with mill tests certificates

Hassle-free customs documentation

Port-to-site shipment coordination

Whether it’s a bulk shipment for a government infrastructure project or a custom order for a private contractor, RAHA GROUP consistently ensures superior quality and, moreover, timely delivery to every client.

Commitment to Quality and Standards

Quality assurance is the foundation of RAHA GROUP’s reputation. Each product undergoes multi-stage inspection and is backed by mill test certificates (MTCs) verifying compliance with relevant standards.

Iran Steel Rebar Manufacturer and Supplier

As one of the largest producers of steel in the Middle East, Iran has built a strong industrial base dedicated to manufacturing high-quality steel rebars for both domestic use and export.

Moreover, the country’s steel sector has grown rapidly in recent years, thanks to modern production facilities and the availability of abundant natural resources such as iron ore and energy.

Overview of the Iranian Steel Rebar Industry

Iranian steel rebars are known for their durability, strength, and adherence to international standards like ASTM and BS, making them a preferred choice for large-scale infrastructure and construction projects across Asia, Africa, and Europe.

Moreover, prominent manufacturers — including Mobarakeh Steel Company, Esfahan Steel Company, and Saba Foulad Zagros — have made substantial contributions to the nation’s overall production growth and global recognition.

Among the many reputable names in this industry, RAHA GROUP stands out as a trusted supplier of steel rebars that meet international standards for strength, durability, and performance.