Introduction of MEG

Mono Ethylene Glycol (MEG) is a colorless, odorless, and hygroscopic liquid chemical with the formula C₂H₆O₂, produced primarily by the hydration of ethylene oxide. It is one of the most important intermediates in the chemical industry, widely used in the production of polyester fibers, polyethylene terephthalate (PET) resins for bottles and packaging, and as a key ingredient in automotive antifreeze and coolants.

MEG also finds applications in de-icing fluids, heat transfer fluids, solvents, and as a building block for various chemical products. Its versatility and essential role in textiles, plastics, and industrial processes make it a critical raw material for many growing economies worldwide.

Chemical Cornerstone in Central Asia’s Industrial

Mono Ethylene Glycol (MEG) is a crucial chemical intermediate, and its demand is a powerful barometer of industrial growth. For the Central Asian nations of Uzbekistan and Turkmenistan, MEG has become a key commodity, fueling rapid expansion in local manufacturing sectors.

Applications of MEG in Uzbekistan & Turkmenistan

- The Textile Industry (Polyester Fiber) Uzbekistan, in particular, has a strong and growing textile industry. MEG is a vital raw material for producing polyester fibers, which are essential for synthetic apparel, home furnishings, and other textile products. The ongoing push for domestic value-added production in the textile sector directly correlates with an increased need for MEG.

- Packaging and Plastics (PET Resins) The rising consumer demand for bottled beverages and lightweight packaging in both countries is significantly boosting the need for Polyethylene Terephthalate (PET). MEG is a key component in PET resin manufacturing, making it crucial for the packaging and plastics conversion industries.

- Automotive and Industrial (Antifreeze and Coolants) Given the extreme temperature variations in the region, MEG’s use as an antifreeze agent and coolant for automotive and industrial machinery remains a consistent and vital application. It is also used in other industrial applications like solvents and hydraulic brake fluids.

Imports & Trade Data in Uzbekistan

In 2023, Uzbekistan imported about US$10.6 million worth of ethylene glycol (HS 290531) worldwide. Major source countries: Iran ($7.82 million), Russia (~$1.79 million), Turkey (~$0.65 million), etc.

Market Trends & Challenges

Demand likely rising due to textile, PET, and industrial growth. Price fluctuations depending on global feedstock prices (ethylene, natural gas) and logistics. Challenges: purity grades, cost of import vs local production, regulatory and environmental requirements.

Imports & Trade Data in Turkmenistan

Turkmenistan is planning or building capacity to produce MEG (Mono ethylene glycol) domestically. The planned capacity for MEG is about 190,000 tons/year. This would make MEG both an export significant and import substituting product. Turkmenistan is also importing MEG

Delivery to Major Cities and destination in Turkmenistan and Uzbekistan

We offer timely and secure delivery of Mono Ethylene Glycol (MEG) to major cities. Our network comprises strategic places, offering convenient distribution to your destination. Some of the key cities where we can deliver goods to you:

- Tashkent

- Fergana

- Namangan

- Andijan

- Bukhara

- Samarkand

- Navoi

- Ashgabat

- Turkmenbashi

- Mary

- Dashoguz

- Türkmenabat

- Balkanabat

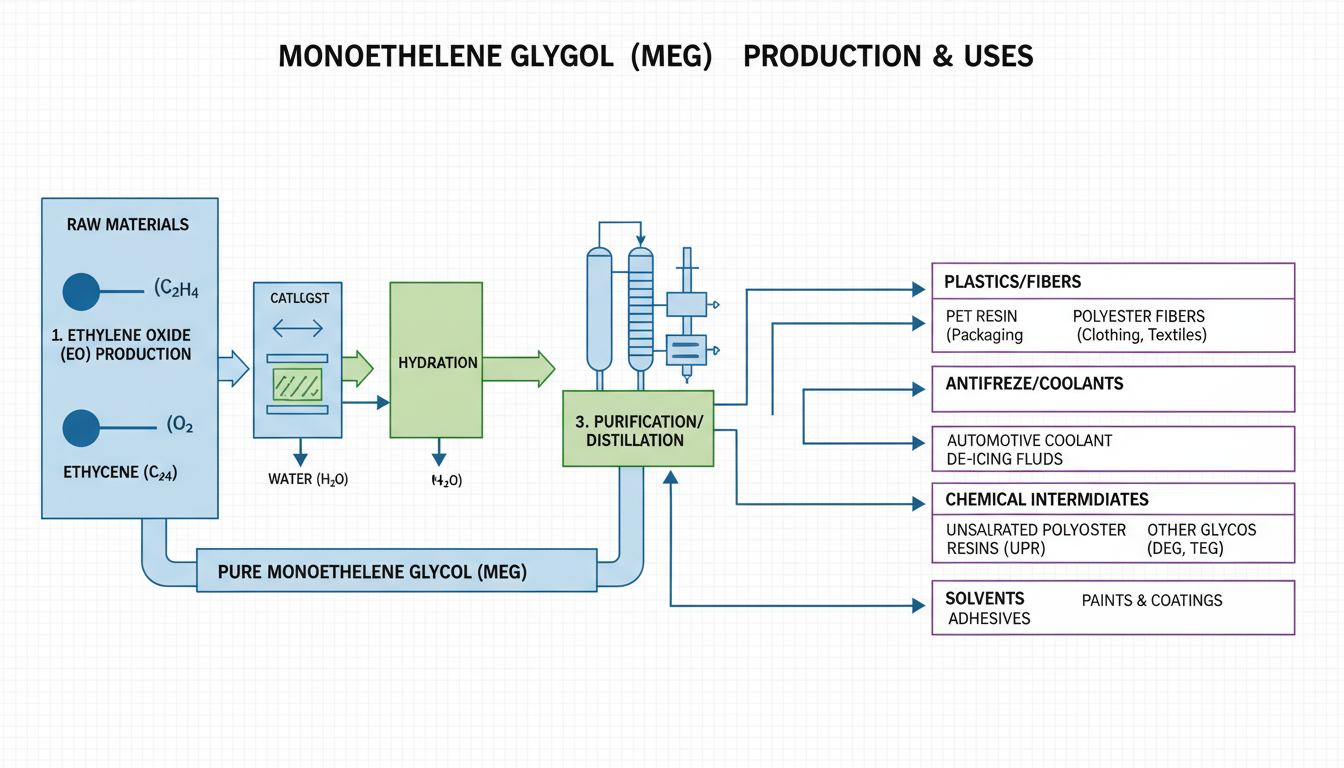

Production Process of Mono Ethylene Glycol

Safety Tips of Mono Ethylene Glycol

Here are some key safety tips for handling: Wear chemical-resistant gloves, safety glasses, and a respirator in poorly ventilated areas. Always work in well-ventilated areas and avoid contact with skin and eyes. Wash hands thoroughly after handling and store MEG properly labeled in a cool, dry location. In case of spills, contain the spill and seek help for large spills. For small spills, wear PPE and use absorbent materials to clean up.

Specification of (MEG)

| Appearance | Colourless, transparent |

| Purity | 99.8 wt % min |

| Colour (Pt-Co) | 5 max |

| DEG | 0.08 wt % max |

| Water | 0.08 wt % max |

| Specific gravity, 20/20 C | 1.1151-1.1156 |

| Boiling range at 0.1013 Mpa | - |

| 5% vol | Min. 196 C |

| 95% vol | Max. 199 C |

| Aldehydes (as formaldehyde ) | 8 mg/kg max |

| Acidity (as acetic acid) | 10 mg/kg max |

| Iron (as Fe) | 0.1 mg/kg max |

| Inorganic chlorides (as Cl) | 0.05 mg/kg max |

| Ash | 50 mg/kg max By Req=10 mg/kg max |

| UV Transmittance | - |

| -220nm | 80 min |

| -275nm | 95 min |

| -350 m | 99 min |

Specification of Mono Ethylene Glycol